UzAuto Motors to fully restore production in Asaka from July 17

UzAuto Motors plant in Asaka will be fully operational again from July 17. The press service of the company reported that the lines are now being launched gradually. At the beginning of the month, the plant was temporarily suspended due to modernization works.

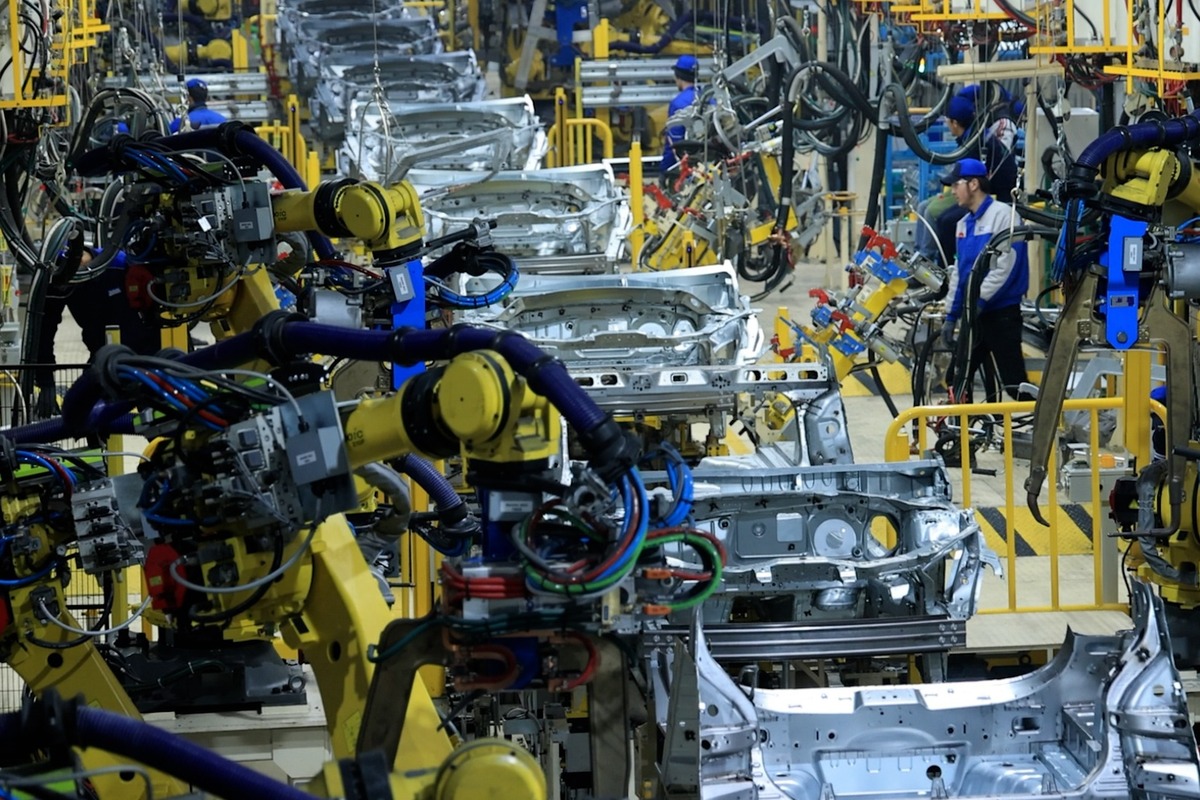

Photo: UzAuto Motors

The UzAuto Motors plant in Asaka will restart at full capacity on Monday, July 17. Currently, the workshops are being launched step by step, the press service of the company informed Gazeta.uz.

Earlier, the company announced that the car plant in Asaka has temporarily suspended operations due to planned modernization work.

It was said that the enterprise, in cooperation with 170 specialists from South Korea and other countries, is launching a planned modernization of the factory's production lines in order to increase production capacity and ensure sustainable production.

As part of the modernization plan, it was planned to develop and start up the software of the new Fanuc (Japan) robotic system in the pressing shop, and to replace the conveyor rails in the painting shop, provide maintenance to the robotic systems in the shop, and test all the systems working in the painting process.

The company announced that the production speed of two lines of the assembly shop will be increased, that is, the production speed of the first line will be increased to 35 units (h/car), and the second line will be able to increase this indicator to 30.

Modernization will increase the annual production volume of all car models. Modernization of the second line allows to increase the annual production volume of Chevrolet Cobalt by 30 thousand units. In 2022, the company produced more than 101,600 cars of this model.

It was also noted that this will not affect the schedule of delivery of cars to consumers.

Recommended

List of streets and intersections being repaired in Tashkent published

SOCIETY | 19:12 / 16.05.2024

Uzbekistan's flag flies high on Oceania's tallest volcano

SOCIETY | 17:54 / 15.05.2024

New tariffs to be introduced in Tashkent public transport

SOCIETY | 14:55 / 05.05.2023

Onix and Tracker cars withdrawn from sale

BUSINESS | 10:20 / 05.05.2023

Latest news

-

Uzbekistan leads Central Asia in medal count at FISU World University Games in Germany

SOCIETY | 12:23

-

Tashkent Metro to suspend train service at six more stations for maintenance

SOCIETY | 12:07

-

High spending and shady contracts: Anti-Corruption Agency launches probe into Khanabad music festival

BUSINESS | 22:25 / 26.07.2025

-

Soaring gasoline prices and consumer rights issues spark debate in Uzbekistan

POLITICS | 19:50 / 26.07.2025

Related News

12:30 / 16.01.2025

UzAuto Motors still dominates Uzbekistan’s auto market with over 350 thousand car sales

17:04 / 15.01.2025

UzAuto Motors retains 8.5 trillion UZS profit after declaring new dividends

15:31 / 04.01.2025

Saidazim Gulyamov appointed Acting Director General of UzAuto Motors Powertrain

12:54 / 28.12.2024