“The plant, which occupies an area of more than 40 hectares, previously did not operate at full capacity and was unprofitable. In this regard, it was transferred to the jurisdiction of the joint stock company “Uzbekistan Railways” and modernized in 2013. In recent years, the localization of production has been significantly expanded, which has increased the economic efficiency of the plant,” the statement says.

Today the enterprise is capable of producing 1,200 and repairing 1,500 freight cars per year. The plant produces six types of freight cars, including semi-open, closed, with a long wheelbase, and those intended for transporting grain, cement, and mineral fertilizers.

The foundry shop of the plant, worth $120 million, is capable of producing 26 thousand tons of products per year. All types of spare parts used in the operation of railways and the repair of rolling stock are cast here.

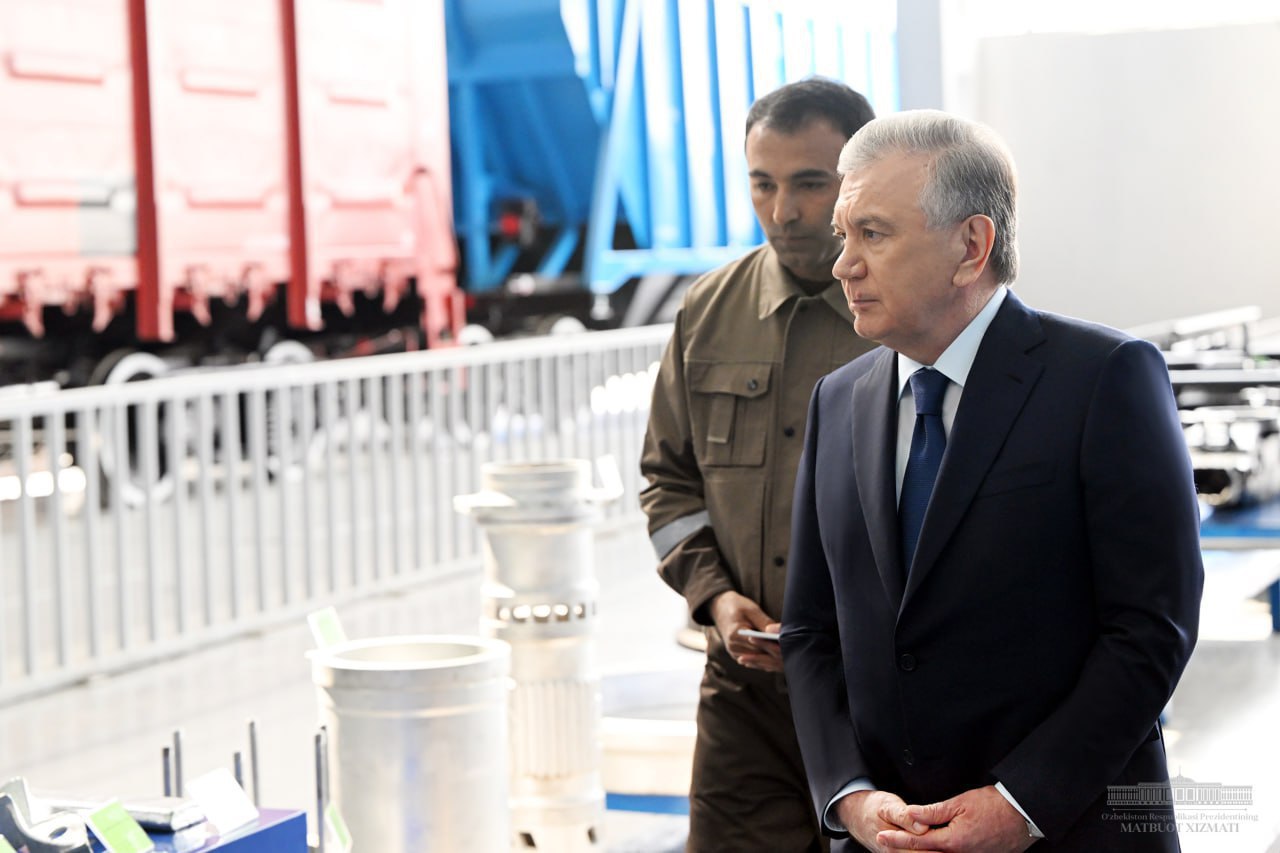

The head of state got acquainted with the products being manufactured.

“Our main goal today is to create more jobs. For example, this year we want to build 100 thousand houses in our country. When will they suit people? When there are jobs close to home. Therefore, in mahallas, as in the case of personal plots, economic projects will be developed taking into account the proximity to apartment buildings. Those who are unemployed will be provided with assistance in finding employment. Such factories play an important role in this,” Shavkat Mirziyoyev said.

It was noted that in the complex it is necessary to increase the production of goods for construction, utilities and other industries, to introduce entrepreneurs to these opportunities, and to increase the number of orders. This, in turn, helps create jobs in related industries.

The plant has 26 workshops, including car building, mechanical assembly, wheel, foundry, repair, pressing, blanking and assembly. The President inspected the production process in these workshops.

In 2018–2023, the enterprise implemented a program to localize the production of about 100 types of products. In 2023, products worth a total of 267 billion soums were produced, 170 wagons and spare parts worth $10 million were exported. This year it is planned to increase the export volume to $15 million.

The plant has implemented international standards for the quality management system ISO 9001 and the energy management system ISO 50001.