In particular, the invention designed to extract gold from ore with a complex composition and difficult to process, created by experts and scientists of the huge enterprise and applied in practice in 2019, became an important innovation in the world mining and metallurgical industry. Based on the use of this new technology by the combine’s “alchemists”, an additional 1.5 tons of gold is currently extracted from waste at the hydrometallurgical plant per year.

The technology of sulphide ore processing was put into practice at the hydrometallurgical plant built in Uchkuduk. This technology covers the oxidation process at the expense of bacteria in nature. Currently, this plant is the largest of 18 plants in the world in terms of production capacity among enterprises that extract gold based on biooxidation technology.

Sulfide ores are complex and difficult to process. Therefore, a certain amount of gold remains in the ore waste from the hydrometallurgical plant. This is a problem common to all hydrometallurgical plants in the world that process this type of ore. That is, carbon or sulfur surrounds a precious metal, like a candy wrapped in paper. It is necessary to “bite the nut” and extract the core. In this process, not all “nuts” are cracked. The technology created by the combine’s scientists is specialized in “biting nuts that don’t crack”. This process is carried out by filtering, drying and incineration.

“Our factory belongs to the category of factories where the most advanced technologies are used in the world. The filtering, drying and incineration workshop was built on the basis of technologies developed by the combine’s experts. This technology is designed to extract gold from complex ore with high efficiency. The first step towards the creation of this technology was taken in 2009, during 10 years many research and development works were carried out in the laboratory of our factory. The results of these researches have been patented in the Intellectual Property Agency as a new technology. It was an invention of world importance. Proposals to work together on the basis of this patent began to arrive at our combine from other countries. The invention aroused great interest especially among German experts. As a result, the German company and the specialists of our combine jointly obtained a German patent for the technological equipment to introduce our patented technology into production. This technology is environmentally friendly,” Shakhobiddin Akhmedov, deputy chief engineer of the hydrometallurgical plant, said.

The complex, which was completed in a short period of time, increased the possibility of processing ores of complex composition.

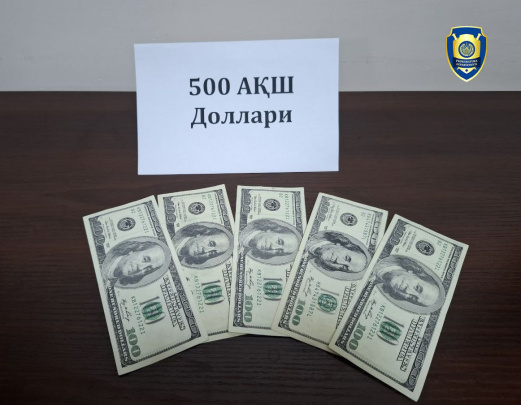

“In the beginning, not only foreigners, but also experts in the field looked at our work with a little distrust. Because our work was based on a new theory, and as a result, it was far ahead of its time. This work of ours is based on the results of many years of painstaking research under the leadership of Professor Kuvondik Sanakulov, a well-known scientist and practitioner of the field, and concrete proofs and evidence. During 2009-2019, we conducted more than 3 thousand different experiments on this topic. That’s why we didn’t back down, we finished the work. First, we received a patent in Uzbekistan, and then in Germany. We gave lectures on our work at international conferences held in Kazakhstan, Russia and Germany and returned with 1st degree diplomas. As a result of the introduction of these patents into production, our plant receives an additional 1.5 tons of gold from waste every year,” Dr. Ulugbek Ergashev, deputy head of the technological department of NMMC JSC, said.

This invention is a new and unique technology in the processing of minerals with complex composition. For the first time in the history of the mining and metallurgical industry of Uzbekistan, the invention was awarded the gold medal of the World Intellectual Property Organization under the United Nations Organization. In the initial project, the rate of extraction of gold from waste in the complex built on the basis of the invention was determined to be 62%. Avaz Kolonov, deputy chief engineer of the hydrometallurgical plant, said that this figure has now reached 76%:

“Our plant is designed to process sulphide ores. In 2008-2009, a biological oxidation process was started at our plant to extract gold from the sulphide enrichment. We extracted up to 85% of gold from the biologically oxidized product. The remaining 15% went to waste. With the introduction of new technology, we were able to extract most of the 15% gold in this tailings. The main advantage of the technology is that it is energy-efficient, environmentally friendly, has a large production capacity and is fully automated.

This invention of “alchemists” of the combine made it possible to reduce the cost due to the production of additional finished products from waste at the factory. NMMC JSC continues to create such new technologies and implement effective proposals.